Home » Lab Capabilities » Pharmaceutical Development

Formulation Development

From API to Product!

Our comprehensive R&D formulation capabilities combined with our tightly integrated analytical expertise, allow us to support you in advancing your pharmaceutical innovations. Our services leverage a multidisciplinary approach to design formulations, taking into account factors such as bioavailability, stability, and manufacturing scalability.

Our knowledge spans a wide range of medicinal dosage forms, providing not only cutting-edge solutions but also tailored problem-solving and troubleshooting strategies.

As we are CMO independent, we select the best manufacturing facility for your product.

From reverse engineering, through in-depth research and development, up to small-scale GMP batch manufacturing, we are dedicated to accelerating your product’s journey to market. Partner with Avivia to streamline your drug development process and achieve faster, more efficient outcomes.

Avivia is an independent pharmaceutical development contracting organization in the Netherlands offering a unique, complementary range of pharmaceutical services in the areas of:

Pharmaceutical Development Services

In the dynamic landscape of the pharmaceutical industry, the development and production of high-quality and effective drug formulations are integral to meeting the diverse healthcare needs of the global population. Pharmaceutical Formulation Services play a pivotal role in this intricate process, offering comprehensive solutions to pharmaceutical companies, research institutions, and manufacturers.

These specialized services encompass a spectrum of activities, ranging from the conceptualization of a drug formulation to its final production and market release. The formulation of pharmaceuticals involves a delicate balance of active pharmaceutical ingredients (APIs), excipients, and delivery systems to ensure optimal efficacy, safety, and patient compliance.

Avivia Pharmaceutical Formulation Services leverage a multidisciplinary approach, combining expertise in pharmaceutical sciences, chemistry, and engineering. They collaborate with clients to design and optimize formulations, taking into account factors such as bioavailability, stability, and manufacturing scalability. This collaborative effort ensures that the developed formulations meet regulatory standards while aligning with the specific therapeutic goals of the drug.

Moreover, in an era marked by rapid advancements in technology and an increasing demand for personalized medicine, Pharmaceutical Formulation Services continue to evolve. They integrate innovative approaches such as nanotechnology, controlled release systems, and novel drug delivery methods to enhance the performance of pharmaceutical products.

Small Scale GMP

Having decades of hands-on experience with a wide range of (complex) pharmaceutical formulation technologies and many different types of drug formulation and medicinal products, the experts of Avivia Pharmaceutical Development Service are able to fully execute and/or support the development of any pharmaceutical finished dosage form, formula or process, as well as to transfer a developed product from our pharmaceutical laboratory to our new small-scale GMP production area or scale-up to a manufacturing facility.

With our pragmatic and creative development mentality, we deliver what a client needs. We perform best by exploring together the motivations behind their request.

Our pharmaceutical laboratory formulation development services are supported by strong in-house analytical, dissolution and excipient characterization service platforms.

Pharmaceutical Formulation Development Services

Medications exist to treat or prevent disease in man, animal and beyond. For a medication to deliver its drug substance effectively and safely into a patient, it generally must be formulated into a drug product. Thus, pharmaceutical formulation development is required to transform a promising drug substance into a commercial drug product. The main goal of pharmaceutical formulation development is to develop and optimize a drug product tailored on patient needs.

Challenges of pharmaceutical formulation development differ for new chemical entities (NCEs) and generic products. For NCEs, only a small fraction of discovered drug substances and formulated drug products will successfully reach the market. As costs of development and pressure to release new drugs rise, it becomes increasingly important to efficiently develop and select pharmaceutical formulations. Extensive knowledge of physicochemical properties and subsequent behavior of drug substance and drug product helps greatly in speeding up the development. For generics, complex drug products can be difficult to develop. Understanding these formulations in detail can boost generic development.

A successful pharmaceutical formulation needs the pharmaceutical ingredient(s) to be combined with suitable inactive excipients. The type of dosage form greatly affects which excipients must be combined with the drug substance. Excipients can be added in merely to serve as bulking agents to control dose content uniformity during processing. However, excipients can also serve a more functional role. For example, excipients can control drug release rate from the drug product. Where excipients serve functional roles, the importance of compatibility of excipients with the active pharmaceutical ingredient is greatly increased. Importantly, for a drug product to be effective, safe and commercially viable, it must be sufficiently stable. Pharmaceutical formulation development also addresses physicochemical and microbiological stability of drug products.

Achieving consistent drug delivery is becoming increasingly more complex. The finding that many NCEs are poorly soluble does not help. Therefore, drug product formulations for these drug substances are becoming increasingly more complex as well. The same can be said for generics. Here, physicochemical analysis and deformulation or reverse-engineering the originator product can significantly reduce development risks.

Avivia offers solutions for these challenges, either in the form of on-off problem-solving or in the form of a full pharmaceutical formulation development procedure. Interested? Get in touch with us!

Complex drug product formulations

The execution of many patent workarounds on complex drug products fuels our creative thinking and problem solving. This enables us to attack the most difficult CMC challenges. We love challenges!

Scale up and GMP

Our gained phamaceutical scale up and manufacturing expertise/activities yielded a worldwide covering network of CMO’s with whom we are able to accommodate nearly all products and technologies.

Problem solving and troubleshooting

We can do more than implement a solution! We work with the customer to come up with a more effective solution, confirm they’re solving the right problem, or even help them completely redefine the scope of the problem.

Pharmaceutical Formulations

Most medications are taken in by mouth in the form of tablets or capsules for oral delivery. However, this route of administration and these dosage forms are not applicable in all cases. Where targeted delivery is desirable, other forms and routes may be more suitable. For example, in treating atopic dermatitis a topical corticosteroid cream or ointment may be more therapeutically desirable than a systemic corticosteroid tablet or capsule. This is because the drug will be locally distributed onto the place of action and therefore will be effective where it is needed, while reducing the risk of systemic adverse effects.

The following types of formulations are available.

They can be roughly divided in two ways:

Route of administration

- Oral

- Parenteral, i.e.: intravenous, intramuscular, subcutaneous

- Topical

- Transdermal

- Oromucosal

- Sublingual

- Buccal

- Ocular

- Nasal

- Auricular

- Rectal

- Vaginal

- Pulmonary

Dosage forms

Dosage forms are tailored for their intended route of administration. The most commonly applied dosage forms in man are:

- Tablet

- Capsule

- Solution

- Oral suspension

- Oral emulsion

- Injection

- Gel

- Cream

- Ointment

- Paste

- Eye drop

- Eye ointment

- Nasal drop/spray

- Ear drop

- Suppository

- Ovule

- Pessary

- Inhalation device

Avivia has concrete hands-on experience with the formulation development of the previously mentioned dosage forms. Interested? Get in touch with us!

Examples of recent sponsor projects

- 3D printing

- Nano-milling

- Silica loading

- Degradable and non-degradable systems

- Implant technology

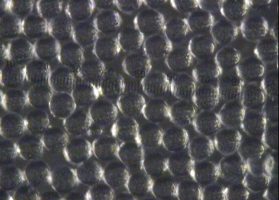

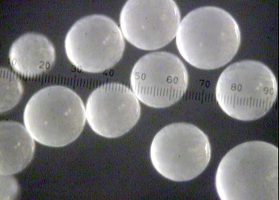

- Microspheres

- Controlled release coatings

- Controlled release matrix

- Taste masking

- Abuse-proof formulations

- Solubility enhancement

Pharmaceutical Formulation development

Avivia has a pharmaceutical laboratory infrastructure and a flexible small-scale GMP production area with state-of-the-art equipment such as:

• Extrusion

• Spray-drying

• Nano-milling

• Tabletting

• Encapsulation of solids and/or liquids

• Aseptic filling or sterile manufacturing of injectables (vials)

• Blending

• Granulation (high and low shear, fluid bed)

• Vacuum drying and stability cabinets

• Lyophilization

• Stability enhancement

• Material matching (primary and secondary packaging)

• Terminal sterilization (e.g. autoclaving; dry heat sterilization; γ irradiation)

• Liquid- and semi-solid mixing & filling